Vacuum Thermal Forming

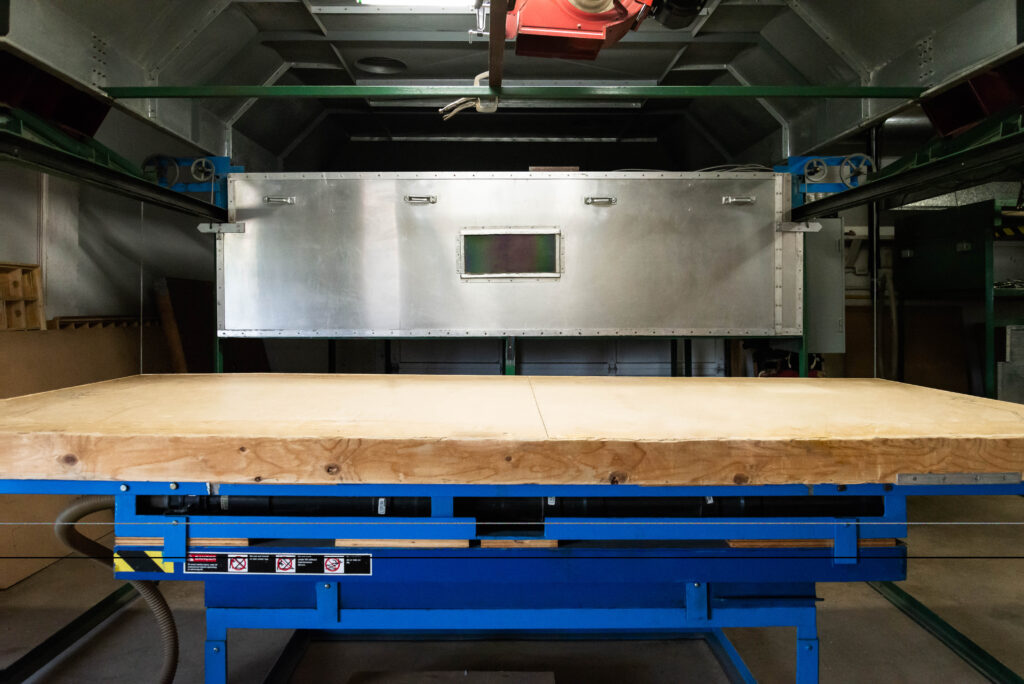

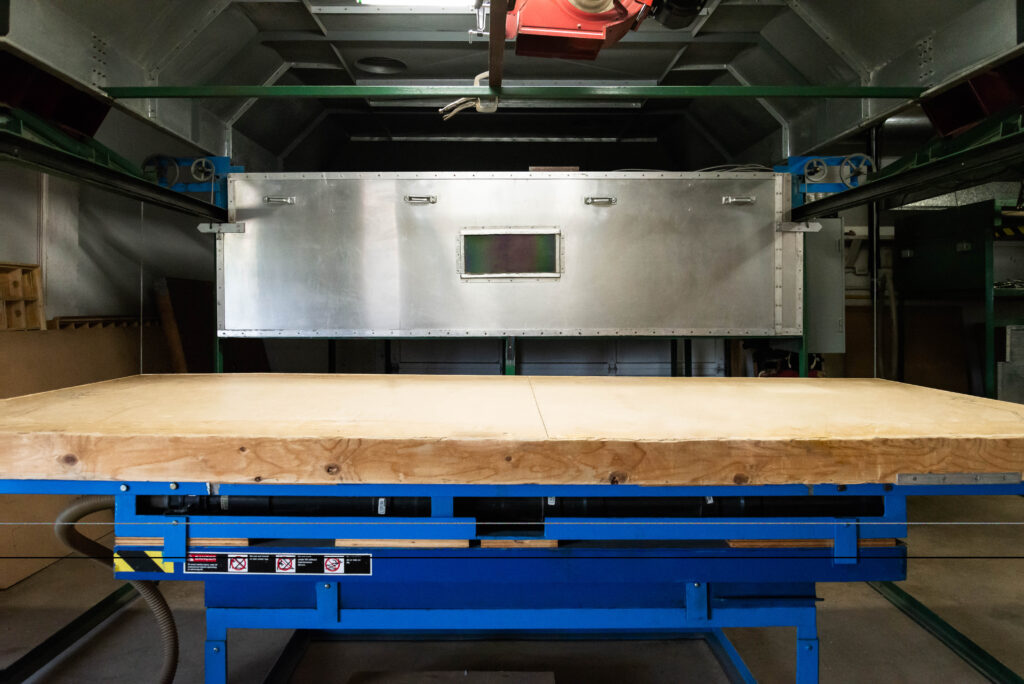

The process of forming plastic of various thicknesses through heating, stretching, and vacuuming using various mold materials. Some of the products we offer include transparent skylight domes and gardening & hydroponic trays.

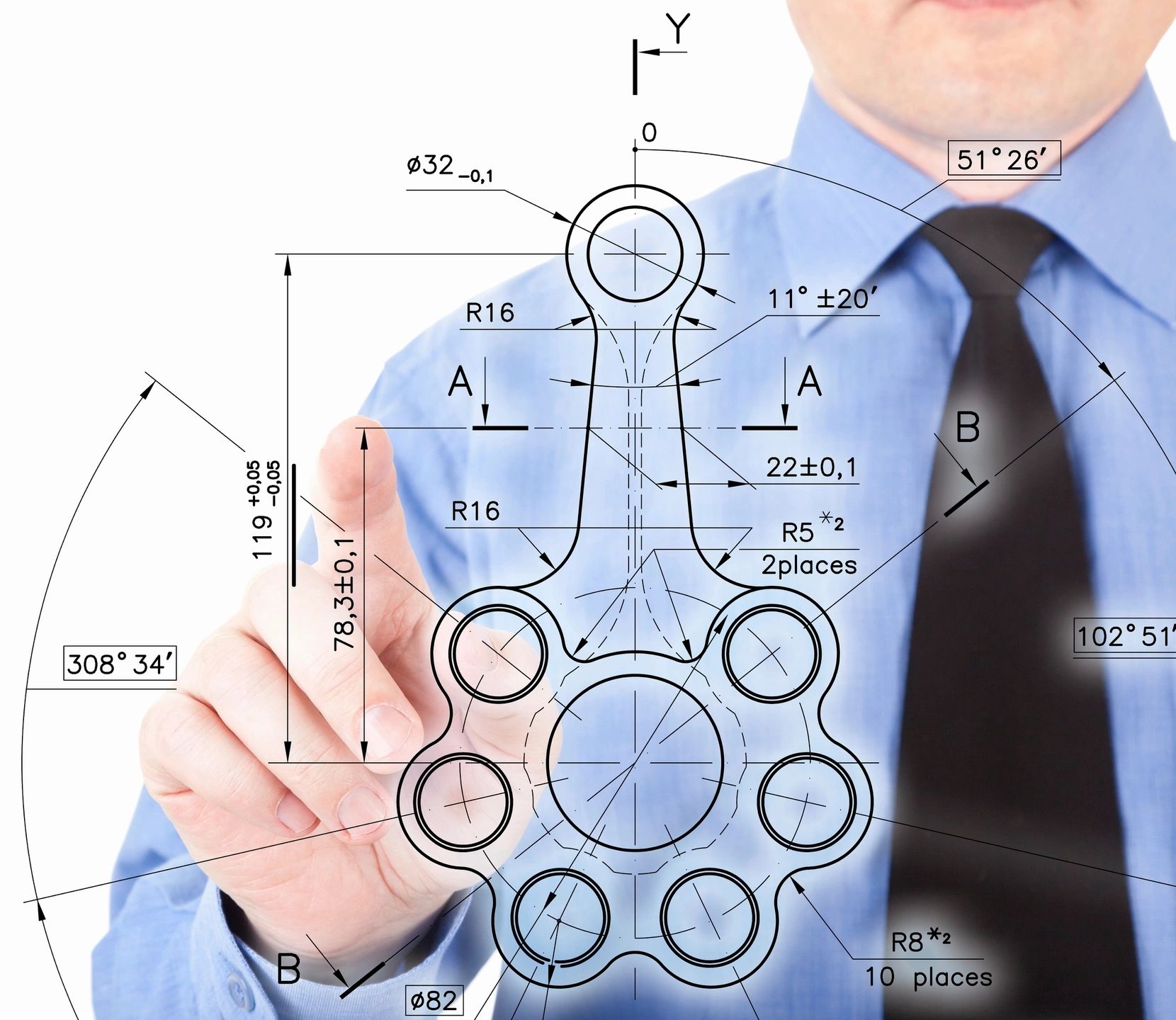

Our team includes talented professionals who are able to assist you with conceptual 3D rendering and printing. There is no project too large or small that we cannot handle.

The process of forming plastic of various thicknesses through heating, stretching, and vacuuming using various mold materials. Some of the products we offer include transparent skylight domes and gardening & hydroponic trays.

The process of heating a hollow mold then filling it with melted plastic pellets. The mold is then rotated on spindles to form a solid plastic to the inner walls with the desired consistency specified. Some of the products we offer include auto parts, sports equipment, and a variety of plastic bins.

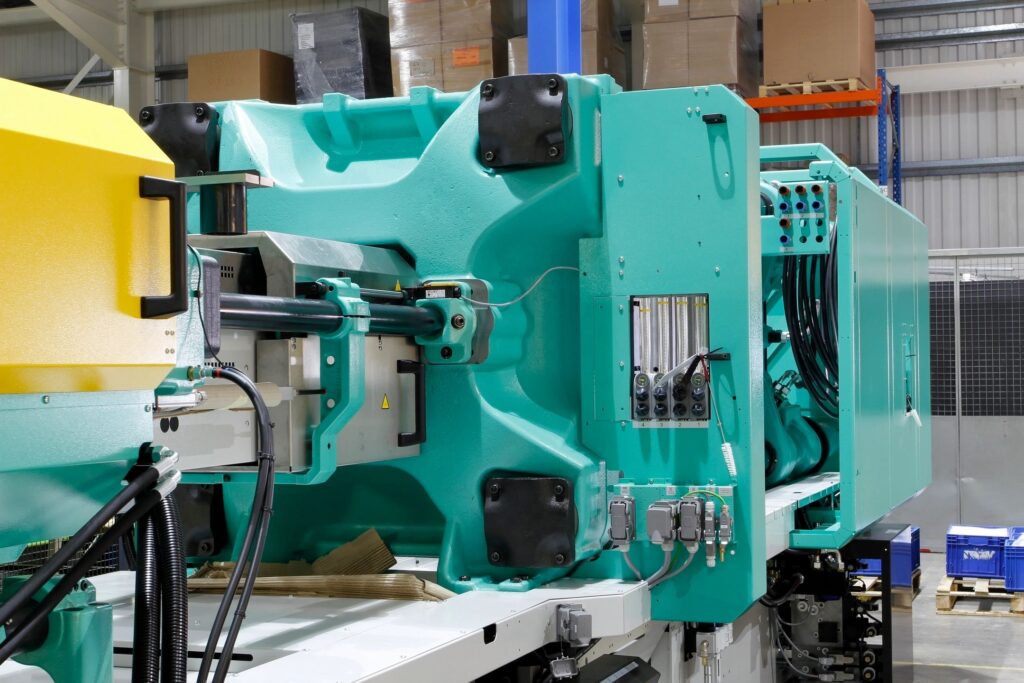

The process of producing a solid plastic product by way of injecting molten plastic beads through a specific rigid mold. Some of the products we offer are agricultural valves, personal protection equipment, and tool handles.

Our affiliate group of companies offer a wide array of services such as high precision CNC routing, turning and milling. We take pride in offering these complimentary services to our clients in-house.

VTF is not limited to production but can also offer various options on finishes to enhance your final product. We offer product brand labels, identification tags, and water transfer surface printing specific to the end user’s needs. We take pride in offering in-house processing.

We design and supply quality packaging for our clients to ensure the products arrive intact. We also offer custom and pre-engineered hard cases to further protect sensitive equipment and parts using CNC foam inserts and complimentary composite and metal bracketry.